By 2030, Duravit will reduce its CO2 by 20% – and here’s how • Hotel Designs

Even in 2022, sustainability remains a buzzword that is fast losing its meaning, with brands using the term without purpose as a way to ‘level up’ and stand out. Therefore it is refreshing to see extensive research, development and progress from companies with the mindset to pull together in order to evolve manufacturing processes across the industry, with the unapologetic aim to set new standards. By working together, and sharing learnings, we as an industry are able to deliver a stronger punch through the noise around sustainability and conscious design.

The stated objective of the UN climate conference COP 27, which took place from November 7 to 18 in Egypt, is to put an end to global warming and its devastating consequences for our climate. While the members of the United Nations’ Framework Convention on Climate Change define the guiding principles for sustainable action at a global level in Sharm El Sheikh, every one of us can play our part today in putting less strain on the environment. There are a range of approaches to increased sustainability – including in the bathroom, which is why we decided to hear from one bathroom manufacturer that is making considerable changes.

Image credit: Duravit AG

Preserving resources reaps sustainability benefits

Preserving resources is one of the key measures we can take to protect the environment. Saving energy releases fewer greenhouse gases into the atmosphere and lower water use prevents soils from drying out. Preserving resources is important for increasing sustainability in the bathroom. This benefits the end customer as it almost always means cost savings – an attractive incentive, especially in times of rising energy prices.

Practical Duravit technologies that can be retrofitted in any bathroom boost cost savings without reducing comfort. For example, modern faucets with an additional FreshStart function offer potential savings because only cold-water flows in the central position. It is only when the handle is deliberately moved to the left that hot water is added to the mix. The Duravit single-lever mixer thereby ensures economical use of energy and resources – without requiring too much extra thought.

LEDs on mirrors and mirrored cabinets reduce resource usage in the bathroom. The intelligent control dims or turns the light off completely as required. Modern night lights, such as those available with the SensoWash® products, can be individually deactivated as needed. In automatic mode the night light only comes on when it gets dark. Because an LED only consumes 85 mW of electricity, energy consumption is negligible.

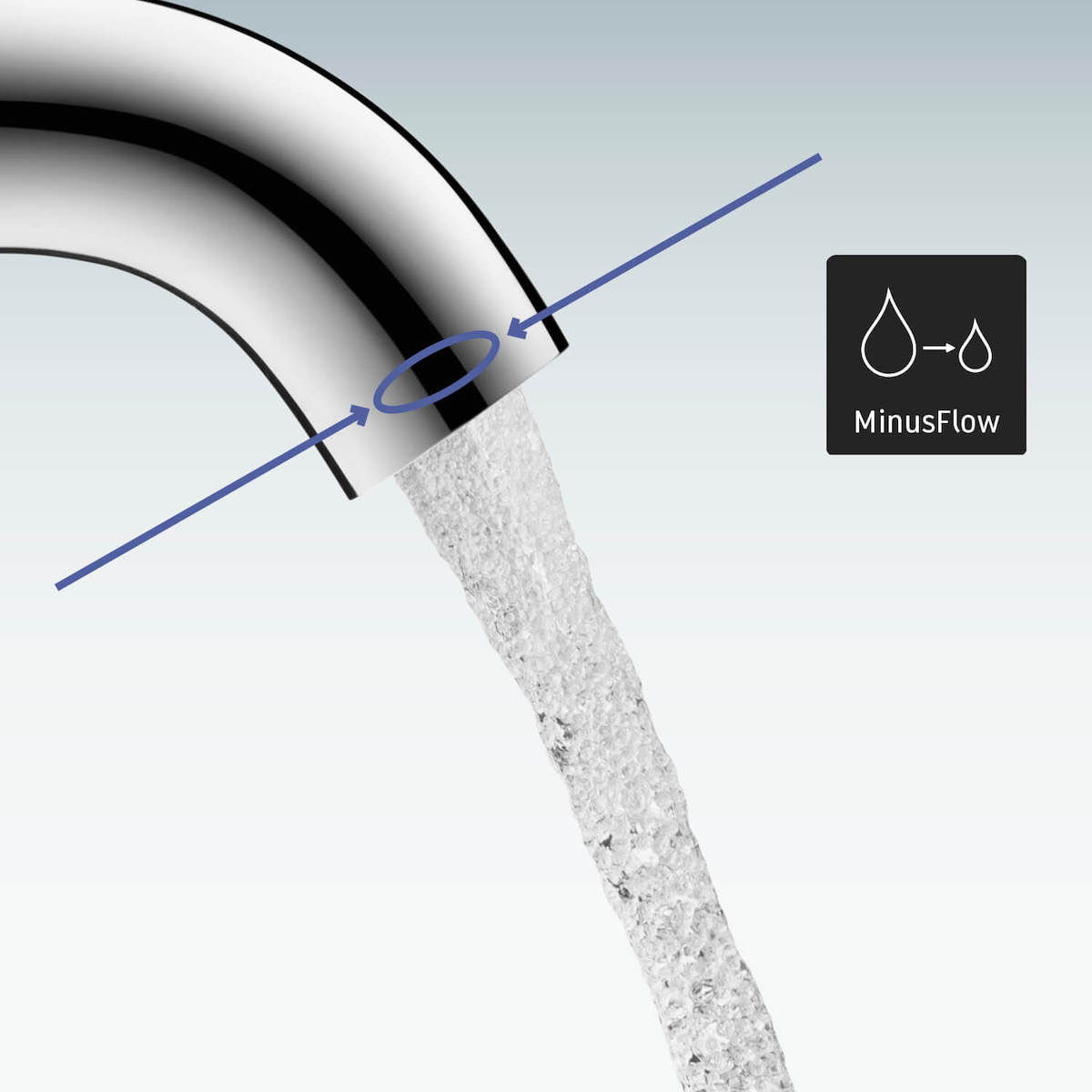

The Duravit faucets with MinusFlow function allow for a particularly efficient use of the ever-scarcer resource of water. Water consumption when washing hands is reduced by up to 40 percent while ensuring an almost equivalent experience, rising to as much as 60 per cent on the showerheads.

- Image caption: Contemporary faucets with the FreshStart function

offer potential savings because only cold water

flows in the central position. Only when the handle

is deliberately moved to the left is hot water added

to the mix. The Duravit AG single-lever mixers

ensure sparing use of energy and resources. | Image source: Duravit AG

- Image caption: The Duravit AG faucets with MinusFlow function

allow for a particularly efficient use of the ever

scarcer resource of water, reducing water

consumption when washing hands by up to 40

percent, rising to as much as 60 percent on the

showerheads, while ensuring an almost equivalent

experience. | Image source: Duravit AG

Water-saving flushing technologies on toilets have a huge impact and already enables savings of 290 million litres of fresh water per year in Europe. Duravit AG has been supplying these for the last 15 years. Similarly, Duravit products bear the UWL label (Unified Water Label), which transparently classifies water consumption for the end user.

Durability – the most sustainable concept of all

Durability is an essential aspect of sustainability. This starts at the planning stage: if bathrooms are planned with foresight – and for instance in an age-appropriate manner – they can promote users’ well-being for decades. Contributing factors are not only manufacturing precision and the highest-quality materials, but also a design that remains timelessly modern.

Ceramic production is Duravit’s origin story. Ceramic is one of the world’s oldest cultural materials. Its stability, robustness, and use of purely natural materials lend it properties that from the outset go a long way to satisfying the requirements for preserving the environment and saving resources. Most ceramic products from Duravit also come with a lifetime guarantee.

Further, durability plays a central role in the selection of materials at Duravit AG beyond ceramics. One example are the toilet seats made from urea, which are more robust in daily use and retain the material’s characteristic sheen even after 15 years. This means they need to be replaced less frequently. Moreover, urea has a lower CO2 impact of up to 30 percent than materials made from oil-based plastics such as ABS or polypropylene.

Image credit: Duravit / Paul Meyer

Duravit AG also constructs further product details such as hinges to be durable. These are made from robust and recyclable metal elements instead of plastic. Drawers for drawer systems as well as hinges and edging bands on pivot doors need to complete 80,000 cycles in demanding product tests to prove their long-term durability. Stainless-steel toilet-seat hinges need to flawlessly withstand 50,000 drop tests. Based on these exacting practical tests, Duravit AG offers a five-year warranty, assuming proper care and use. 15 carefree years are usually possible in practice.

In terms of durability and quality requirements, Duravit faucets fit seamlessly into the complete bathroom provider’s high-quality product portfolio. And not least the customers also benefit here from a five-year voluntary manufacturer’s warranty and a 15-year availability guarantee for spare parts following the discontinuation of a faucet range.

Sustainability as a commercial challenge

The ecological footprint of a product starts much earlier than its delivery to the customer. The key factor above all others is manufacturing. For that reason, sustainability is becoming an increasingly important topic particularly for small and mid-sized enterprises – and is even more essential for a complete bathroom manufacturer such as Duravit AG whose beating heart – ceramic production – is especially energy-intensive.

The company is concentrating on finding ways to reduce both its consumption of resources and raw materials and its emissions as far as possible. As part of the comprehensive package of measures, the manufacturing facilities in Germany already use electricity generated exclusively from renewable energies. Some internal solutions continue to reduce energy and resource requirements during the manufacturing process. Waste heat is also consistently reused. PEFC-certified furniture production that adheres to the principles of sustainable forestry as well as “local for locals” production methods that ensure shorter transport routes are further key aspects of the portfolio of measures.

Image credit: Duravit AG

Recycling and avoidance of waste are also part of resource preservation. For example, Duravit Group uses 60 per cent recycled water at its oldest company site in Hornberg alone and has constantly been able to reduce the proportion of fresh water used. Similarly, packaging for Duravit ceramics consists of up to 80 per cent recycled wastepaper and is 100 per cent recyclable. The active recycling of paper, cardboard, cartons, PE and PP plastics, wood, aluminum, steel, and sheet metal reduces emissions by some 320 tonnes of CO2 in Germany alone.

Duravit AG is constantly striving to further increase the use of recycled or recyclable material in its production processes. For example, a centrifuge is being planned at the Hornberg site that is intended to filter out raw materials from manufacturing waste and feed it back into manufacturing processes. Ten percent of the material – some 550 tonnes a year – could be reclaimed in this way. Sustano – the first recyclable shower tray made from the mineral cast material DuraSolid® Nature developed in-house – was launched in 2022.

Because that is not enough for the illustrious company, Duravit AG has embarked on an ambitious and comprehensive climate mission. The goal: to be an exclusively climate-neutral business around the world by 2045.

The family-run company from the Black Forest, which operates in over 130 countries, aspires to use CO2 offsetting as little as possible. The company is determined to accomplish its mission: “We are in the process of questioning old certainties and investing in finding and implementing new ways of achieving a sustainable future,” underlined CEO of Duravit AG, Stephan Tahy. “A key milestone for the company is to reduce CO2 by 20 per cent by 2030 compared to 2019 levels.”

Image credit: Duravit AG

Potential measures are currently being reviewed and evaluated – including sourcing electricity from renewable energies around the world, combining oxygen and green hydrogen to reduce emissions, as well as powering electric kilns with green electricity. Additionally, Duravit AG is assessing how it can increase its use of recycled materials and is commissioning studies on binding CO2 emissions locally – just a small part of the sustainability package that the company is constantly reviewing and expanding.

Given that sustainability is always a collective task, Duravit AG has joined numerous initiatives: The “Green Building Council” (USGBC), the Deutsche Gesellschaft für Nachhaltiges Bauen (German Association for Sustainable Construction, DGNB) as well as the Institut Bauen und Umwelt (Institute of Construction and the Environment, IBU), which awarded the designer bathroom manufacturer the Environmental Product Declaration (EPD) for the product groups ceramic, sanitary acrylic, and DuraSolid® A. Additionally, Duravit AG is a partner and funder of the Schwarzwald Mitte/Nord natural park.

Duravit is one of our Recommended Suppliers and regularly features in our Supplier News section of the website. If you are interested in becoming one of our Recommended Suppliers, please email Katy Phillips.

Main image credit: Duravit